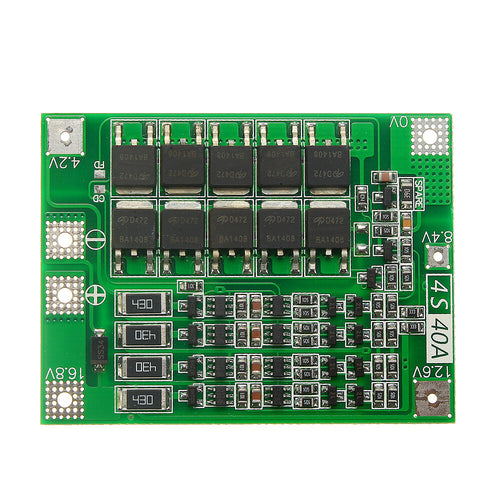

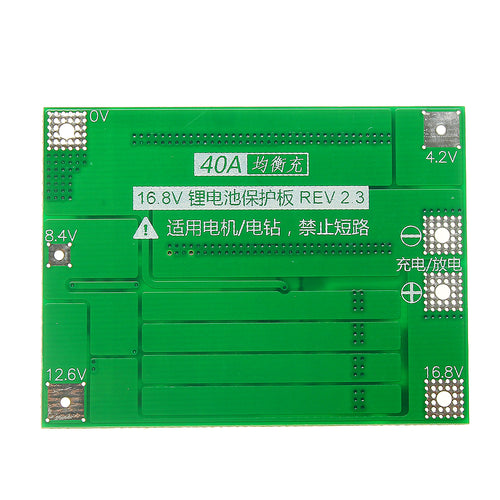

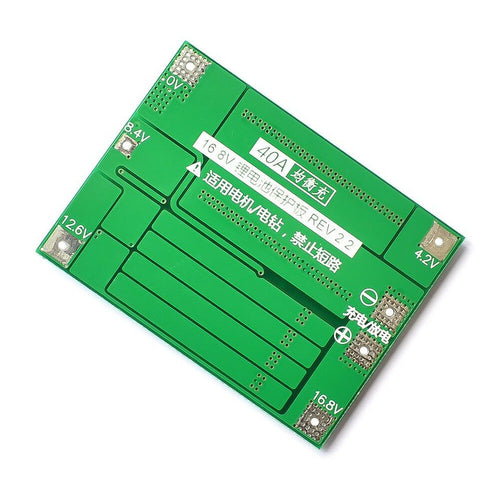

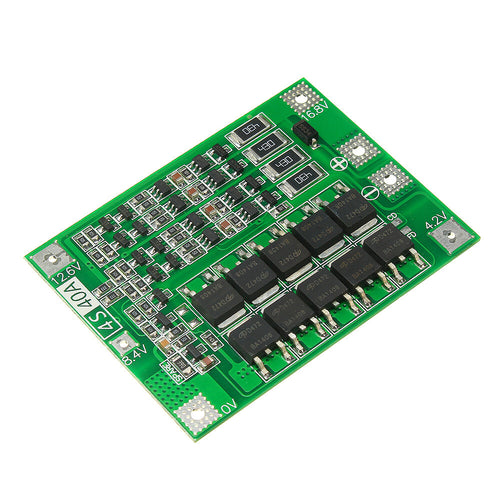

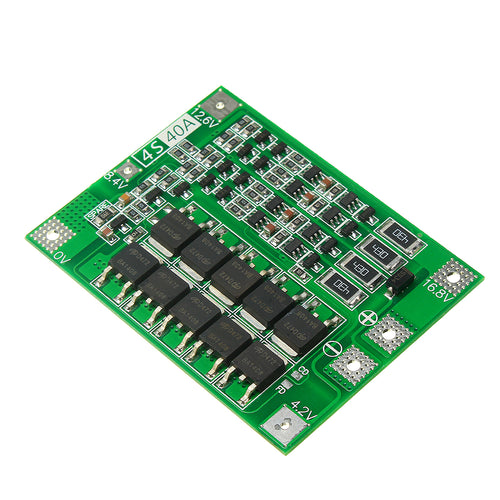

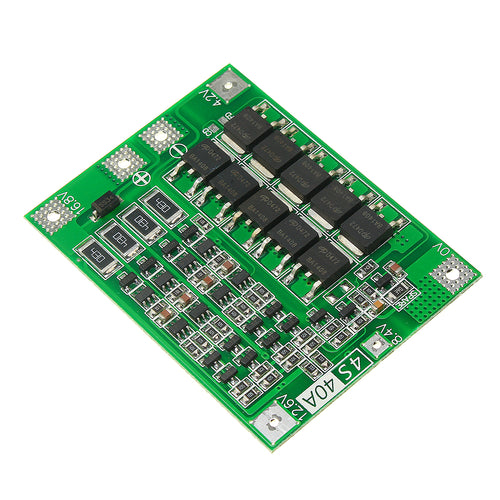

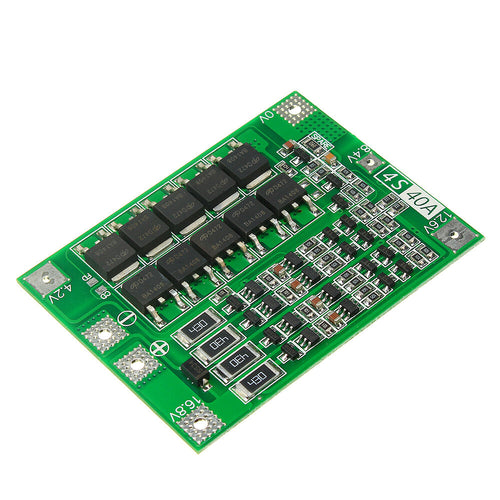

4S 40A Li-ion Lithium Battery 18650 Charger PCB BMS Protection Board with Balance For Drill Motor 14.8V 16.8V Lipo Cell Module

- Problemlose Garantie

- 30 Tage Geld-zurück-Garantie

- Schneller, kostenloser Versand

- Lebenslanger Kundensupport

Feature:

4 string 16.8V 40A lithium battery protection board (comes with recovery function-AUTO Recovery)

Scope: Nominal voltage of 3.6V, 3.7V lithium battery (including 18650,26650, polymer lithium battery)

Product Size: 45 * 55 * 3.4mm (Standard Edition / Enhanced), 46 * 60 * 3.4mm (balanced version)

Product weight: 9.3g (standard / enhanced version), 10.3g (balanced version)

Charging voltage: 16.8V - 18.1V

Continuous discharge current (upper limit): 40A (if the cooling environment is not good, please reduce the load current use)

Continuous charge current (upper limit): 20A

Equalization version: suitable for starting current below 80A, power 135W below the drill.

Project

Min.

Typ.

Max.

Units

Consuming current

12

18

24

uA

Overcharged protection voltage

4.2

4.25

4.3

V

Balanced starting voltage

4.17

4.2

4.23

V

Equilibrium current

95

100

105

mA

Balanced heating power

1.56

1.72

1.91

W

Overcharge recovery voltage

4.1

4.15

4.2

V

Over-discharge protection voltage

2.4

2.5

2.6

V

Overvoltage protection after over-discharge protection

2.8

3

3.2

V

Overvoltage protection after over-discharge protection

3.2

3.5

3.8

V

Over-discharge recovery voltage

2.9

3.2

3.3

V

Conduction internal resistance

2.5

3

3.5

mQ

Overcurrent protection current C

70

80

90

A

Overcurrent delay time

100

150

200

ms

Continuous operating current

0

40

40

A

Continuous output power

0

672

672

W

Ambient temperature

-40

25

85

°C

Troubleshooting:

Fault phenomenon

Fault check and cause

The solution

Unable to charge

Measuring the voltage of 4 groups of batteries.

when one of the battery voltages exceeds 4.25V,

the protection board will activate overcharge protection.

Pair the battery pack well, do not mix

the good battery and the bad battery.

Unable to discharge

Measuring the voltage of 4 groups of batteries.

when one of the battery voltages is lower than 2.7V,

the protection board will activate the over-discharge

protection.

Pair the battery pack well, do not mix

the good battery and the bad battery.

Charging/discharging

failure

OV, 4.2V, S.4V, 12.6V, 16.8V miswired

Rewire or replace the new board

(human failure, no warranty)

Overcharge/overdischarge

failure

OV, 4.2V, 8.4V, 12.6V, 16.8V miswired

Rewire or replace the new board

(human failure, no warranty)

Discharge protection

Check that the battery pack has sufficient discharge

capability and check that the load's starting current

exceeds the overcurrent protection current of the

protection board.

Replace the battery pack with a higher

discharge capacity, or a protective

plate with a larger current

(super working range)

Component soldering

There is no connection between one of the components

and the PCB pad.

Repair welding

Component welding

There is a short circuit between two or more pins of the

component.

Remove the component and re-weld

Electrostatic breakdown A

In the unpowered state, measure the G, D, and S

poles of the MOSFET. If the forward and reverse

resistances of any two pins are 0Q,

it indicates that it has broken down.

Remove the replacement MOS tube

Electrostatic breakdown B

Remove the MOS tube and measure the resistance

of the G and D, G and S poles of the MOS tube.

If there is a resistance indicating that it has broken

down, the resistance should be infinite.

Remove the replacement MOS tube

Package includes:

1 x Battery Protection Board